21 March 2024 | Nuremberg

bayernhafen Nürnberg and bayernhafen Roth ready to meet the challenges and demands of state-of-the-art logistics locations

2023 financial year: 3.98 million tonnes of cargo and freight moved by inland waterway and rail; combined transport throughput totals 318,471 TEU; 230,000 truck journeys saved

In the past year, 3.98 million tonnes of cargo and freight were moved by inland waterway and rail at bayernhafen Nürnberg and bayernhafen Roth, amounting to 92% of the total tonnage moved in the previous year. (image attribution: bayernhafen / E.Wechsler)

Nuremberg, 21.03.2024 – 3.98 million tonnes of cargo and freight were moved by inland waterway and rail at bayernhafen Nürnberg and bayernhafen Roth in 2023, amounting to 92% of the total tonnage moved in 2022. Around 230,000 road trips were saved by shifting long-distance traffic to the more environmentally friendly transport modes of inland waterway and rail. In 2023, bayernhafen moved 8.23 million tonnes of cargo and freight by barge and train at its six ports in Aschaffenburg, Bamberg, Nuremberg, Roth, Regensburg and Passau. As developments within the ports typically echo trends observed in the broader business landscape and the economy at large, the freight handling figures are also a reflection of the current situation.

Rail freight transport in 2023 totalled 3.748 million tonnes, a decrease of 6.8% on 2022. Combined transport throughput at bayernhafen Nürnberg totalled 318,471 TEU (1 TEU = one twenty-foot standard container), down 10.7% on the previous year. In addition to containers for seaport-hinterland traffic – primarily with Hamburg, Bremerhaven, Rotterdam and Verona Freight Village – continental cargo and freight transport includes swap bodies and semi-trailers. 230,037 tonnes of goods were moved by inland waterway, 19% down on 2022. The inland waterway and rail networks facilitate the efficient transportation of all manner of goods, including agricultural produce, construction materials, metals, foodstuffs, fuels, recycling materials, minerals, and industrial products such as plant machinery, automotive components, as well as heavy-lift components such as prefabricated garages.

A port serves as a seismographic indicator of developments in the economy.

Joachim Zimmermann,

Chief Executive Officer of bayernhafen

In heavy-lift cargo handling, a significant volume of heavy-lift and over-sized bulky goods were shifted away from the road networks and on to the waterways. Such freight is ideally suited for transportation via barge, alleviating pressure on road networks and mitigating potential bridge damage. At bayernhafen Nuremberg and bayernhafen Roth, around 125 components were moved, totalling almost 14,000 tonnes (4% up on 2022). bayernhafen Roth is a main transhipment point for boiler systems, while Nuremberg mainly handles transformers and refrigeration units. “For the local companies operating in the large transformer and heavy machinery construction sector, this infrastructure is crucial not only for their initial decision to locate here, but also for their continued presence,” says Ingmar Schellhas, who has co-led Hafen Nürnberg-Roth GmbH (the operator of bayernhafen Nürnberg and Roth) with Joachim Zimmermann since November 2023. “We maintain ongoing dialogue with the more than 200 companies based here to address important future topics, including modern port infrastructure, efficient space utilisation, digital transformation, sustainability and emerging business models,” says Schellhas.

The repercussions of the war in Ukraine, the shift towards clean and renewable energy sources, and the palpably felt economic downturn are unmistakably mirrored in the port’s freight handling statistics. “A port serves as a seismographic indicator of developments in the economy,” says the Chief Executive Officer of bayernhafen, Joachim Zimmermann. “However, as the focus sharpens on environmental protection and the shift to sustainable transport, the port’s role as a central hub gains increasing significance. Inland ports are poised to play a pivotal role in facilitating a successful transition to clean energy sources, fostering a more robust circular economy, and promoting sustainability in heavy-lift transport. The essential prerequisite for this evolution remains a high-performance infrastructure, ensuring the seamless integration of inland waterway, rail and road transport within the logistics chain.”

In 2023, bayernhafen sustained its commitment to substantial investment, allocating approximately €27 million to the redevelopment of its commercial sites and port infrastructure, with over €4 million being invested in its Nuremberg location. “Through long-term investment in our trimodal port infrastructure, we are making a valuable contribution to the future of sustainable transport. Notably, the companies operating from bayernhafen’s ports are leveraging this phase, augmenting their investments in existing corporate locations and establishing new service links. Nevertheless, it remains evident that a pivotal factor in achieving the envisioned modal shift in the future lies in addressing the substantial need for infrastructure modernisation in Germany, encompassing the rail network, locks, and bridges. We need stable conditions, significantly accelerated approval processes and robust protection for the port infrastructure to facilitate this transformative progression,” says Joachim Zimmermann.

Outlook for 2024

The redevelopment of the quays at bayernhafen Nürnberg is taking shape, with the first construction phase nearing completion. The modernisation of bayernhafen’s ageing infrastructure will result in significant optimisation of cargo and freight-handling facilities for the companies operating from the Nuremberg location. In addition, flexible mobile handling equipment will ensure our quay facilities are fit to meet the demands of cargo and freight handling in the future. The aim is to put the right quay facilities in place to fulfil all environmental protection regulations. Quay 1, located to the north, will be redeveloped in the second construction phase. Divided into three construction phases, the dismantling and drainage work will also commence in the first phase. The work is scheduled to be completed during the course of the year. bayernhafen plans to follow this up with the redevelopment of Quay 3 and 8.

We are also in constant dialogue with the more than 200 companies based here to address important future topics surrounding modern port infrastructure, the efficient use of space, the digital transformation, sustainability and other new business models.

Ingmar Schellhas,

Chief Executive Officer of Hafen Nürnberg-Roth GmbH

The recycling company and processing centre ‘Die grünen Engel’ (‘The Green Angel’), based at bayernhafen Nuremberg, stands for the energy-efficient recovery of high-grade secondary raw materials from construction, commercial and industrial waste. Durmin has been operating from the port since 1996 and is on a steady course to growth. The signing of the lease for a 3-hectare site at Quay 1 will increase its portfolio to a total area of around 16 hectares. Durmin intends to make a double-digit million-euro investment at the new site in various processing plants for mineral and non-mineral waste and products. Waste transport will occur, among other means, via waterways by inland waterway vessels, as the site at quay 1 and the recycling material are well-suited for this purpose.

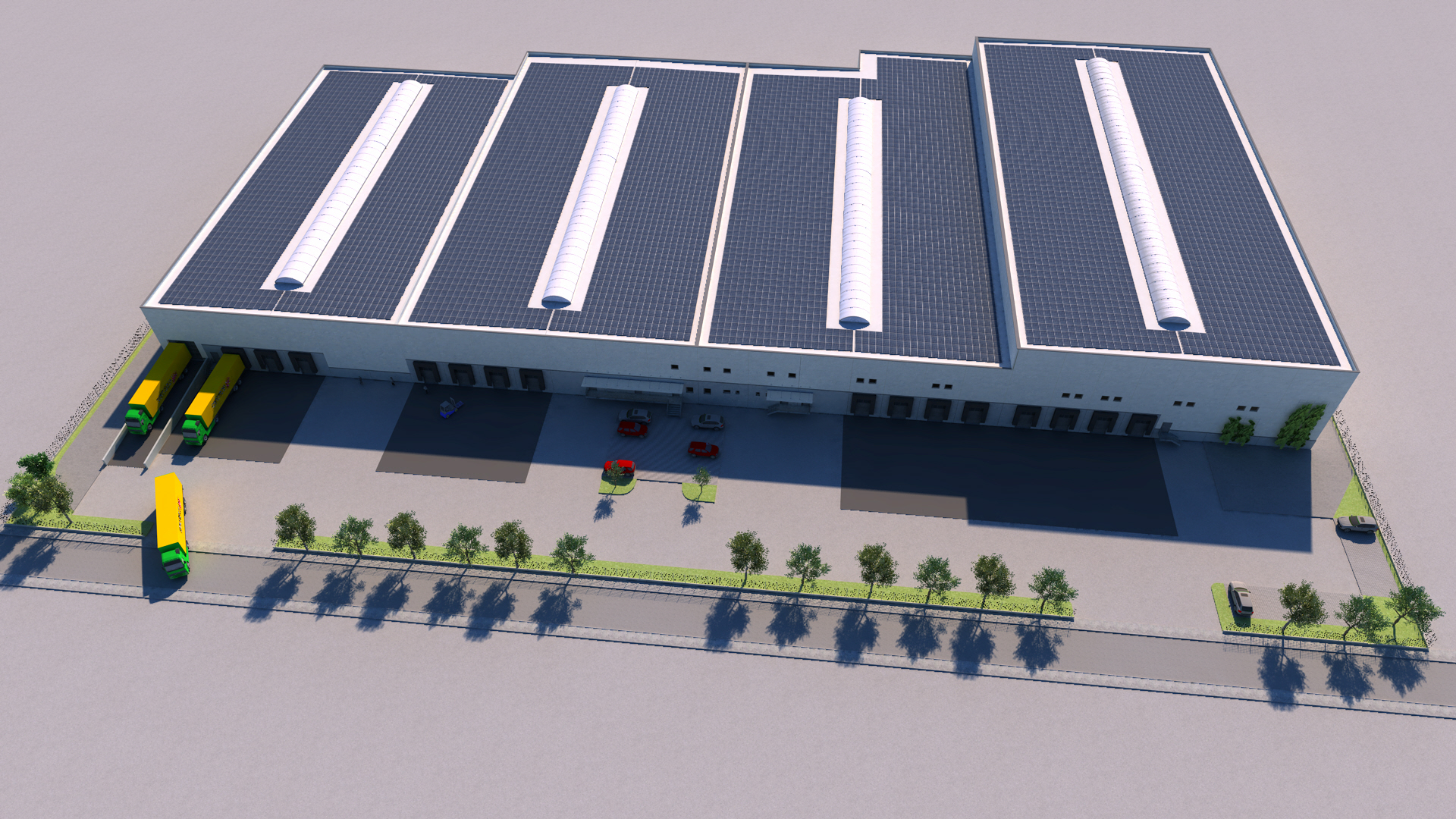

The Rhenus Group is expanding its capacities at Quay 2 located to the north through the construction of a new logistics facility that will provide state-of-the-art storage, freight handling areas and office space. Of the total 40,000 m² of existing space at Kai 2 in Nuremberg, 17,000 m² will be completely newly built. The new facilities are scheduled to enter into operations at the end of Q2 2024. This is a prime example of commercial development of existing space through strategic site conversion.

The redevelopment and expansion of the CT terminal at bayernhafen Nürnberg is also currently in progress. As previously reported, the development work being carried out on Module 1 will not involve any interruptions to normal terminal operations. The construction work for the HGV access and loading lanes and the parking lanes for loading units will be completed by the end of 2024. The new cranes are expected to be delivered and be up and running by the end of 2026. The investment means that the CT terminal, which has now reached the limit of its capacity since entering into service in 2006, will gain a 21% boost in crane capacity to handle a total of 400,000 TEU.